Solution

Application of stepper servo Motor system in precision counterpoint platform

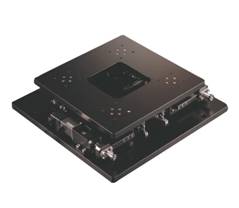

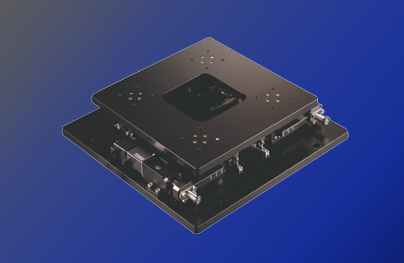

Precision counterpoint platform is a platform with small stroke, high precision and extremely fast contraption speed. Compared with the traditional X-y-platform, it has advantages such as compact structure, ultra-thin, hollow and extremely fast contraption speed, etc. After being coordinated with machine vision, it is suitable for high-precision processes such as lamination, printing, hot pressing and lamination, and has the following characteristics:

● High accuracy, within 5 m

● High speed and alignment time within 1S is required

● The size of the motor is small, fast speed and high precision

● Hollow size, space for machine vision photography, trachea, etc

A well-known precision counterpoint platform manufacturer in Taiwan has experienced the following three solutions

1.Step motor

Although the traditional stepper motor has the advantages of low cost and simple use, the customer rejected the scheme of the stepper motor because of the risk that the stepper motor would miss the step all the time.

Phase of the project demonstration, the customer has considered the compromise of the stepper motor with encoder, but doing so although have solved the problem of out-of-step, brought other issues accordingly: the encoder signals must be processed by the controller, control not only complex, the system response is slow, but also increase the cost of hardware and software of control and the cost of debugging.

2. Servo motor

At present, the minimum installation size of the servo motor is 40×40mm. Moreover, as ac servo motor adopts 220VAC power supply, it will take pictures of machine vision. If the anti-interference process is not good, the photos will often be interfered and polluted.

The stepper servo motor (closed-loop stepper motor) can achieve a minimum of 28×28mm, and the use of DC 24VDC power supply, not only to machine vision and more sophisticated instruments will not produce interference and pollution.

| Platform size: 150mm×150mm Stroke: + / - 7.5 mm x + / - 7.5 mm x 2 ° Mechanical structure: ball screw + guide rail + cross roller bearing Screw pitch: 2mm Accuracy: + / - 5 microns Maximum speed: 100mm/S Alignment speed: < 1S Dynamic load: 30kg Static load: 100kg | |

3.Stepper servo motor

| Model: 28 emc - HB Frame: 28 mm Torque: 0.14 N.m Encoder: 10000PPR Maximum speed: 3000rpm |

Using shenzhen zhichuang stepper servo motor (closed-loop stepper motor) 28EMC-HB is as simple and easy as using traditional stepper motor.

Since the driver adopts 32-bit DSP processor, the driver can process the signal of encoder at high speed by itself, without any out-of-step phenomenon. There is no need to increase the cost of hardware and software on the control.

The precision of stepper servo motor (closed-loop stepper motor) is 10000 pulses/laps (same as that of standard servo motor 10000 pulses/laps);

Maximum speed: 3000 RPM;

There is no overshoot or back-and-forth adjustment when stopping, which is very suitable for machine vision.

Most importantly, compared with the traditional servo motor alignment times less, alignment speed greatly improved.

The customer highly recognizes the overall cost performance and thinks that the stepper servo motor (closed-loop stepper motor) has high precision, high speed, and simple debugging. It has almost no requirements for debugging personnel and after-sales service personnel. There is no vibration and noise during the operation of the equipment, and the operation effect is smooth and compliant.

According to the requirements of different customers, Shenzhen Zhichuang provides two series of products, SS series - high function type and ES series - easy to use type, from the cost and use to give customers more choice space, in order to meet different market positioning, truly create value for customers, so as to reflect their own value

Product

Product  Service

Service