Solution

Application of BRUShless DC motor in stirring equipment

The traditional food and cosmetics mixing equipment mostly uses three-phase induction motor.

In the actual use process, the viscosity and viscosity of the agitator changes with the time of agitator,

The output torque of the required motor will also vary.

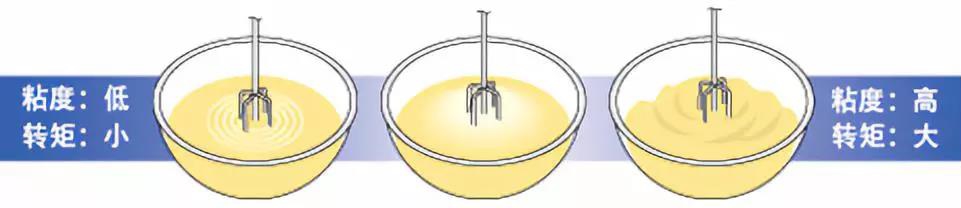

As shown in Figure 1, the higher the viscosity, the greater the torque of the required motor.

However, the three-phase induction motor cannot be controlled by feedback, and the speed will change due to the change of load torque.

When the load is larger, the speed will be greatly reduced, which will not only increase the processing time, but also make the product quality uneven.

In contrast, brushless motors for speed control are more stable.

FIG. 1 Viscosity and torque variation of agitator

Take brushless motor as an example,

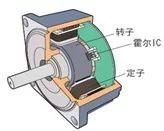

As shown in Figure 2, the motor is equipped with Hall IC. The driver adjusts the motor speed by comparing the feedback signal received from Hall IC with the set speed.

FIG. 2 Structure diagram of brushless motor

Therefore, even if the load condition changes, the brushless motor can still achieve speed control from low speed to high speed and stability.

In addition, the speed control range of brushless motor is wider than that of frequency converter and AC speed regulating motor.

From low speed to high speed, the brushless motor can meet the need to maintain a fixed torque.

Compared with the traditional three phase induction motor, the brushless motor is lighter and thinner in size.

Not only that, brushless motors can be customized with a variety of protection levels, suitable for mixing equipment and other splashed environment.

Product

Product  Service

Service