Solution

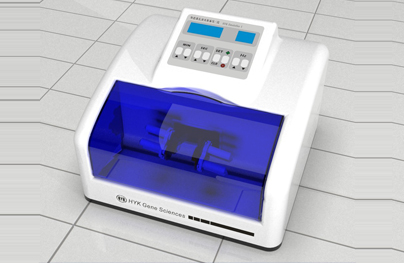

Application of Stepper servo Motor System in gene analyzer

Gene instrument is a kind of high-tech equipment, has the following characteristics: requirement of high precision, in less than 5 microns

requires high speed

requires the size of the machine

external environment pollution-free

An instrument manufacturer experienced the following three scenarios

1.Step motor

Although the traditional stepper motor has the advantages of low cost and simple use, the customer rejected the scheme of the stepper motor because of the risk that the stepper motor would miss the step all the time.

Phase of the project demonstration, the customer has considered the compromise of the stepper motor with encoder, but doing so although have solved the problem of out-of-step, brought other issues accordingly: the encoder signals must be processed by the controller, control not only complex, the system response is slow, but also increase the cost of hardware and software of control and the cost of debugging.

2. Servo motor

At present, the minimum installation size of the servo motor is 40×40mm. Moreover, as the AC servo motor is powered by 220VAC, it will inevitably cause pollution to other equipment of the instrument.

And the closed-loop stepper motor can achieve a minimum of 20×20mm, and the use of DC 24VDC power supply, almost no pollution to other equipment of the instrument

X-axis: horizontal movement left and right

Mechanical structure: lead screw + guide rail

Screw pitch: 2mm

Motion distance: 20mm

Operating requirements: accuracy within 5 m, high speed

3. Stepper servo motor

With the closed-loop stepper motor, it is as simple and easy as using traditional stepper motor.

Since the driver adopts 32-bit DSP processor, the driver can process the signal of encoder at high speed by itself, without any out-of-step phenomenon. There is no need to increase the cost of hardware and software on the control.

The closed-loop stepper motor has an accuracy of 16,000 pulses/laps (higher than the standard servo motor with 10,000 pulses/laps);

Maximum speed: 3000 RPM;

There was no overshoot and no back-and-forth swing adjustment at the stop.

The customer highly recognized the overall cost performance, and believed that the closed-loop stepper motor has high precision, high speed, and simple debugging. It has almost no requirements for debugging personnel and after-sales service personnel. There is no vibration and noise during the operation of the equipment, and the operation effect is smooth and compliant.

Product

Product  Service

Service