Solution

The introduction

V-cut machine is also called PCB board breaker, V slot board breaker, circuit board board breaker, etc.In the process of PCB splicing, the traditional way is manual folding. Although the aging is relatively high, the damage of PCB is often caused by uneven force path and inconsistent stress points of the human working splicing board.The use of V-cut machine solves these problems well. V-cut machine has high efficiency in production, and the CUT connecting board is of high consistency, which will not cause PCB damage. The CUT circuit board has smooth edges, flat layout and no deformation.The intelligent brushless drive system is applied to the V-cut cutter of v-cut machine, which is the core part of V-cut machine.

Brushless motor system description

Brushless DC drive system is a new mechatronics motor with the development of rare earth permanent magnets. It is the product of modern electronic technology, control theory and motor technology.Common DC drive system uses carbon brush for commutation. There are many disadvantages in carbon brush commutation: 1.2. Large electromagnetic interference, large noise and short life;3. Complex structure and high maintenance cost.The brushless DC drive system is similar to the DC motor in motor performance, and the motor has no carbon brush, which fundamentally solves a series of problems caused by carbon brush.In addition, the brushless motor system also has the following advantages: 1. Good controllability, wide speed range; 2.2, high reliability, long working life, simple maintenance and maintenance;3, high power factor, high efficiency, the same power output under the case of energy saving can be up to 40%.The brushless drive system adopts the patented PID+PWM control technology, the speed range is adjusted more widely (100RPM~20000RPM), the speed fluctuation is smaller, the speed stability is higher and the rated speed can reach ±0.5%.

System analysis and customer requirements

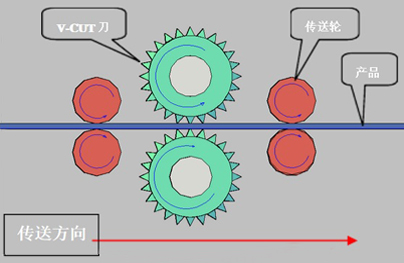

The working principle of V-cut machine is that PCB connecting board is transported to the machine through the roller structure transfer wheel driven by stepping motor, and the cutting work is completed by two V-cut cutters with roller structure.

The following are the requirements of a V-cut machine manufacturer: V-cut spindle motor requires 6000RPM, 750W (ordinary PCB) ~1000W (aluminum substrate) power.

As shown in the figure above, the customer has a V-cut machine equipped with 12 sets of brushless DC drive systems for intelligent innovation.This machine is a 6-tool V-cut machine (a total of 12 V-cut knives). According to the customer's requirements, the engineer adjusted the gain parameters of the driver on site, and controlled the fluctuation of the rotation speed in actual use within 6000±5RPM, which met the customer's requirements for the V-cut spindle motor.The PCB edge is smooth and the board surface is smooth without any deformation, which meets the technical requirements.

Product

Product  Service

Service